OEM Automation Solutions: Pricing, Insights & Product Information for Your Needs

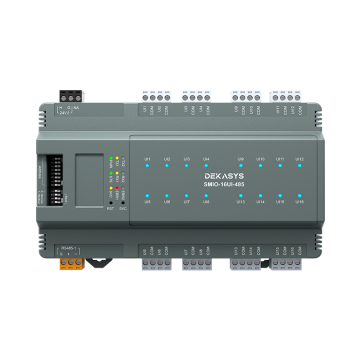

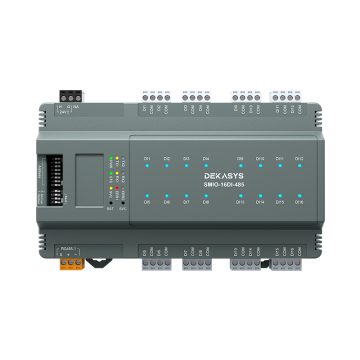

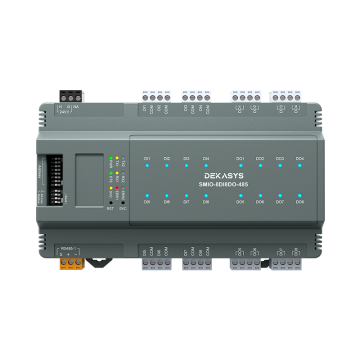

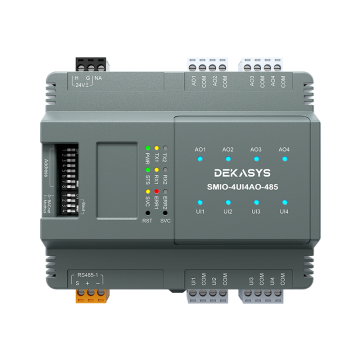

If you seek exceptional Automation Building solutions, you’re in the right spot. As a leading manufacturer based in China, we excel in providing innovative products designed to optimize operations and improve efficiency. Our automation systems cater to a wide range of industries, delivering flexibility and reliability. Understanding the challenges of today’s fast-paced market, we combine cutting-edge technology with user-friendly designs. Count on DEKASYS to offer solutions that enhance productivity and promote sustainable growth. With our extensive experience, we can tailor systems to meet your unique needs effectively.

Step-by-Step Guide To Automation Building More Than a Supplier - A Partner Manufacturer

In today's rapidly evolving industrial landscape, the need for automation has never been more critical. Companies across various sectors are seeking reliable partners who can provide not just components but comprehensive solutions that enhance efficiency and intelligence in their operations. This step-by-step guide delves into how manufacturers can elevate their role from mere suppliers to collaborative partners in Building Automation Systems. Firstly, it is essential to understand the unique needs of your business and how advanced IO modules can integrate seamlessly into your existing infrastructure. By leveraging remote IO technology, companies can manage and monitor their processes with precision, ultimately reducing downtime and maximizing productivity. A partner manufacturer will work alongside you to tailor these solutions, ensuring they align with your specific operational goals. Moreover, a strategic partnership means ongoing support and innovation. Beyond the initial setup, look for manufacturers who provide continuous upgrades and maintenance solutions. This commitment to evolving your automation systems lays the groundwork for long-term improvements in operational efficiency, allowing you to adapt to changes in market demands and technological advancements. By viewing your manufacturer as a partner rather than just a supplier, you open the door to a collaborative relationship that fosters growth and innovation, crucial for sustainability in today’s competitive environment.

Step-by-Step Guide To Automation Building More Than a Supplier - A Partner Manufacturer

| Step | Action | Description | Expected Outcome |

|---|---|---|---|

| 1 | Identify Needs | Assess current processes to pinpoint areas for automation. | Clear understanding of automation requirements. |

| 2 | Research Solutions | Explore various automation tools and systems available. | List of suitable automation solutions. |

| 3 | Evaluate Options | Analyze the pros and cons of each solution. | Informed decision on the best automation tool. |

| 4 | Create Implementation Plan | Develop a roadmap for implementing the chosen solution. | Structured approach to implementation. |

| 5 | Pilot Testing | Run a pilot test of the automation tool in a controlled environment. | Identifying potential issues before full-scale rollout. |

| 6 | Full Implementation | Deploy the automation system across the organization. | Operational efficiency and enhanced productivity. |

| 7 | Training and Support | Provide training to staff on using the new system. | Employees well-equipped to utilize automation tools effectively. |

| 8 | Continuous Improvement | Regularly review and refine automation processes. | Ongoing optimization of workflows. |

Quick Tips To Automation Building Factory Leads the Global Market

J

James Black

I was truly impressed with the quality of the product. The customer service team was prompt and professional, addressing all my concerns swiftly.

21 May 2025

J

Jack King

High quality at a fair price! The customer service team was attentive and capable, enhancing my overall satisfaction.

09 June 2025

L

Liam Brown

I’m beyond satisfied! The quality is top-tier and the support staff was professional and friendly.

25 May 2025

G

Grace Wilson

Remarkable quality! Very efficient and professional customer service made my experience excellent.

29 June 2025

O

Oliver Brown

Superb quality! The support team was very efficient and made the entire experience enjoyable.

30 June 2025

G

Grace Johnson

The quality is exceptional! Plus, the support staff provided excellent guidance.

22 June 2025